Page 2 of 3

Re: Cyclic gain and helicopter size

Posted: Wed 02. Mar 2016 19:57:33

by W.W.

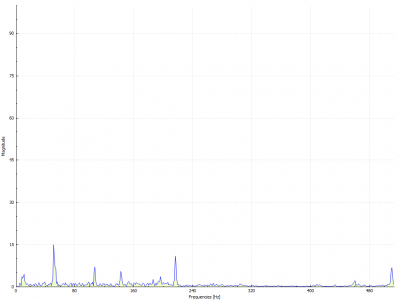

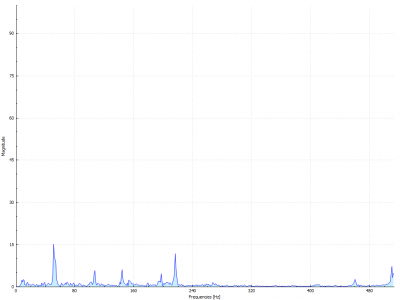

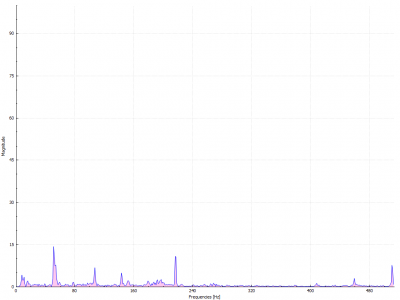

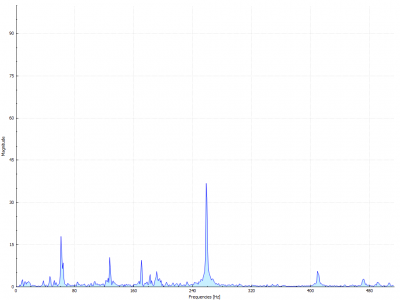

Here are the vibration plots:

3.000 rpm

- 3000 rpm X-Axis

- 3000 rpm Y-Axis

- 3000 rpm Z-Axis

best regards Wolfgang

Re: Cyclic gain and helicopter size

Posted: Wed 02. Mar 2016 19:59:51

by W.W.

and 3.600 rpm

- 3600 rpm X-Axis

- 3600 rpm Y-Axis

- 3600 rpm Z-Axis

every plot without main blades and with tail blades

Checked the bearings => ok

Checked the main shaft => ok

Checked the spindle shaft => ok

Checked the swash plate => very little axial Play => changed by spare => ok

Lowering the belt tension => more vibes (se next posts)

Re: Cyclic gain and helicopter size

Posted: Wed 02. Mar 2016 21:46:26

by W.W.

Re: Cyclic gain and helicopter size

Posted: Wed 02. Mar 2016 21:48:24

by W.W.

Re: Cyclic gain and helicopter size

Posted: Wed 02. Mar 2016 21:49:42

by ZeXx86

Thank you very much for the plots.

The biggest spike is coming from the rudder.

Unfortunately when you mount rudder blades, the spike can be a few times bigger and make a huge troubles.

Without blades there shouldn't be nearly any spike.

Can you mount the tail blades and carefully spin the helicopter to check the analysis?

Re: Cyclic gain and helicopter size

Posted: Wed 02. Mar 2016 23:25:56

by TomasN

ZeXx86 wrote:Thank you very much for the plots.

The biggest spike is coming from the rudder.

Unfortunately when you mount rudder blades, the spike can be a few times bigger and make a huge troubles.

Without blades there shouldn't be nearly any spike.

Can you mount the tail blades and carefully spin the helicopter to check the analysis?

He wrote that the plotes are already with tail blades: "every plot without main blades and with tail blades"

Re: Cyclic gain and helicopter size

Posted: Thu 03. Mar 2016 8:00:05

by W.W.

Correct,

all plots are with tail blades mounted.

Edit: Additionally I can say: Telemetry vibes level in flight was at maximum 12% (normally lower ~7%).

Re: Cyclic gain and helicopter size

Posted: Thu 03. Mar 2016 8:33:53

by ZeXx86

Ah, sorry I have overlooked this.

In this case your plot is looking quite good. At the beginning I can see some low frequency vibration that is pointing that the unit is probably holding not too hard - but this can be caused if helicopter is moving little bit during measurement. If it is mounted with stock tape, then it is OK.

Maybe you can also post your settings so we can check that everything is OK there. But I believe that the problem is somewhere in the rotor head.

If you can observe oscillations on both aileron and elevator axes, then the helicopter is not probably OK. Something must be slightly bent or assymetric.

Maybe the blades are manufactured not too precisely? Normally more expensive blades should be in balance quite perfectly.

Or the last option is bad aileron/pitch servo that is oscillating - if you spoolup helicopter it shouldn't move at all.

Re: Cyclic gain and helicopter size

Posted: Thu 03. Mar 2016 8:53:08

by W.W.

ZeXx86 wrote:Or the last option is bad aileron/pitch servo that is oscillating - if you spoolup helicopter it shouldn't move at all.

The heli moves a little sideways, but only when spooling up on a hard table. When I set It on the service towel there is no movement (when the tail steering rod isn't in place. When It is in place there is some side thrust form the tail rotor in neutral servo position (as recommended by the manufacturer).

I could try to fix the Spirit harder with a velcro strap. Due to bad weather and work times

I couldn't test the latest modifications yet.

My actual Settings are attached. Actually only bank 0 is used until the wobble is fixed.

Re: Cyclic gain and helicopter size

Posted: Thu 03. Mar 2016 9:02:03

by W.W.

ZeXx86 wrote: ... At the beginning I can see some low frequency vibration that is pointing that the unit is probably holding not too hard - but this can be caused if helicopter is moving little bit during measurement. If it is mounted with stock tape, then it is OK.

...

As mentioned before the mounting is:

boom mount | stock tape | 3 mm forex sheet | stock tape | Spirit Pro

This is because the frame is a little to narrow for the Sprit Pro. But the wobble was an issue with the microbeast pro too. There was only the stock tape.

Bend parts in the main rotor are rather unlikely, because everything is already changed:

- main hub

- dampeners

- spindle shaft

- blade holders (including bearings)

- blades

- main shaft

- upper bearing block with bearing

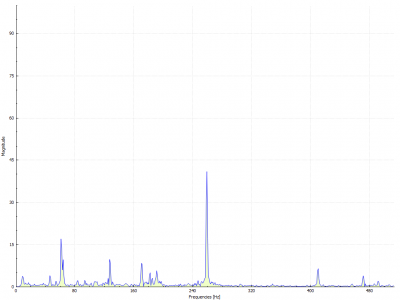

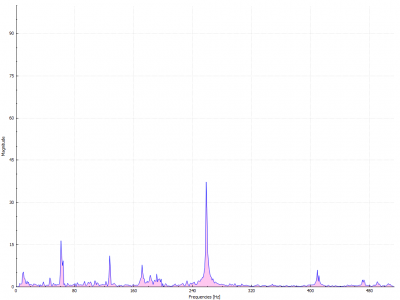

The upper bearing was bad, here Is a plot of the vibrations:

One can see the significantly higher peak at the main rotor head Speed (60Hz = 3600 rpm).